Exclusive: How Union Budget 2022 can push an enhanced EV ecosystem in India?

The government led initiatives like FAME II and Make-in-India have catalyzed electric vehicle adoption in India and triggered an EV demand.

- Multiple govt led initiatives have paved way for EV revolution in India

- Union Budget 2022 is expected to further push EV penetration

- India has committed net zero emissions by 2070 in COP26

Trending Photos

) Image for representation

Image for representation India has positioned itself as one of the leading marketplaces for Electric Vehicles (EVs) globally with many local players now coming up with their electric vehicle offerings. EV adoption can be seen across different vehicle segments as well as different business segments. Favorable plans and policies have been developed by the government like National Electric Mobility Mission Plan (NEMMP), Faster Adoption and Manufacturing of (Hybrid) and Electric Vehicles (FAME) Scheme to drive the transition towards the EV ambition of India.

Adding onto these, many state governments have announced their EV policies with varied focus that would enhance the demand for EV in their respective states. Some states, like Maharashtra and Delhi, have policies aimed at driving the demand, while other states like Uttar Pradesh and Tamil Nadu intend to strengthen the supply side for EVs by encouraging local manufacturing of EVs.

India has also committed to net zero emissions by 2070 in Conference of Parties (COP26) and the country has taken many clean mobility related initiatives to boost EV adoption2. Electric mobility has thus become preferred choice in India owing to the international commitments that India has made, incentives for EV purchases and the efforts and initiatives that are taken for sensitization of the public.

Gaps in the EV industry which can be treated as emerging opportunities

While the government has brought important policy changes, Original Equipment Manufacturers (OEMs) have put efforts to remove barriers through innovations, and consumers have demonstrated readiness and willingness to accept this change, the country still needs to introduce more initiatives to boost the supply side push, including local manufacturing of electric vehicles and components. In terms of value, an EV constitutes of 35% Battery, 25% drivetrain, 20% chassis and 20% systems and other equipment.

Currently, India imports majority of these components as there are limited manufacturing facilities in the country. India has matured in the conventional drivetrain and chassis manufacturing segment, however there is ample room for improvement by manufacturing these for EV specific applications which include lightweight chassis, electric drivetrains, etc.

Also read: IIT develops a new charging system half the cost of current EV tech

Further, EVs are technologically advanced and need semiconductor chips to ensure operations of their electronic components like wireless communications, autonomous vehicle systems, firmware, mobile applications, connected vehicle services and security. Thus, EV manufacturers are facing immense pressure owing to component short fall. It is thus imperative for the government to support the industry in devising innovative strategies to increase domestic manufacturing in accordance with the ‘Make in India’ philosophy.

Along with EV components, there is also a need to enhance the EV charging infrastructure to cater to the rising EV demand. This infrastructure for EV charging comprises of EVSE (Electric Vehicle Supply Equipment), battery storage systems and other related components. These components are assembled to manufacture the final product in India but are still majorly dependent on imports.

Many startups and EVSE SMEs (Small and Medium scale Enterprises) are now focusing on indigenization of these components. This indegenization can be further enhanced with government incentives/rebates and creation of favourable ecosystems for companies to setup manufacturing facilities.

The future of Indian EV ecosystem should be to encourage domestic manufacturing

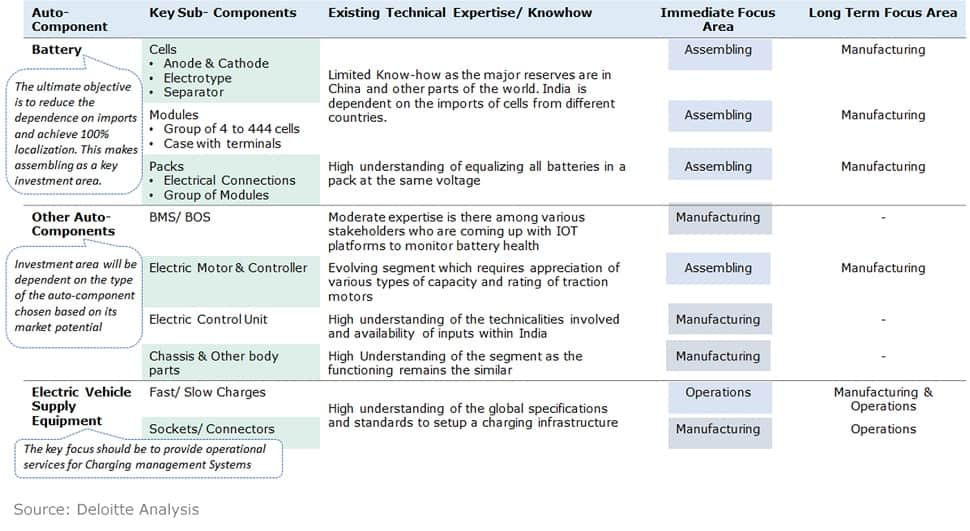

Batteries contribute the largest share of EV cost which is around 35%. Also, the potential for localization of chassis, bodies and BMS (Battery Management System) are high, while localization of specialized components such as batteries and motors could be limited. Moreover, in order to facilitate the localization in India, the phasing of the investments may begin with assembling and then gradually move to manufacturing.

Also read: Updated Tata Nexon EV to get more than 400km electric range

This phased transition will help in import substitution of key auto components and improve its export share, meeting global demand giving a shift towards electric mobility and making India ‘Atmanirbhar’. An indicative phasing strategy for key components has been presented below:

The current budget thus needs to focus on ensuring robust supply of products and services in the EV automotive domain. It should factor in the taxation as well as incentivization mechanisms for EV manufacturing. Various national and state level tax rebates and incentives available for EV manufacturing may be coupled with rigorous implementation plans to boost supply of components and manufacturing EVs. Further, government may create conducive policy environment to support new technology partnerships and tie-ups of international players with Indian players leading to more localization and expansion of EVs’ manufacturing in India.

The supply side can be enhanced further with focused investment in R&D of EVs and EV components to cater to local manufacturing. The workforce also needs to have advanced training and upskilling for the upcoming developments in the EV automotive industry. There is also a need of added incentives and rebates for manufacturing of various EV components to ensure reduced dependency on imports. The import of finished products should be discouraged while encouraging domestic manufacturing.

To facilitate this, the budget can include proposals for manufacturing support specific to the EV industry focused on implementation support to localized manufacturing of electric vehicles and components as well as infrastructure components like EVSE, charger components and connectors.

The author of this article is Sumit Mishra, Director , Deloitte India and Sahil Bhandare, Consultant, Deloitte India. All views are personal.

Stay informed on all the latest news, real-time breaking news updates, and follow all the important headlines in india news and world News on Zee News.

Live Tv

)

)

)

)

)

)

)

)

)

)